A Custom solution is a customer specific solution.

In some cases our Customers has en old machine that needs to work in sync with an existing machine, we can help to implement the necessary actions or changes, that makes the final solution work as expected.

In some cases the machinery is out of sync, and the machines needs a custom solution to make the overall output stable. In some cases this can be solved by implementing a buffer system or another solution to adopt variations in the performance.

To determine the efficiency and impact of a new concept, a Proof of Concept(POC) can be used to test and optimize new processes or mechanical design, to prevent faults caused by the new equipment.

A Proof of Concept typically involves creating a prototype or a minimal viable product (MVP) to showcase the core features and functionalities of the concept. It aims to address key technical and operational questions, assess the viability of the solution, and provide insights for further development or investment decisions.

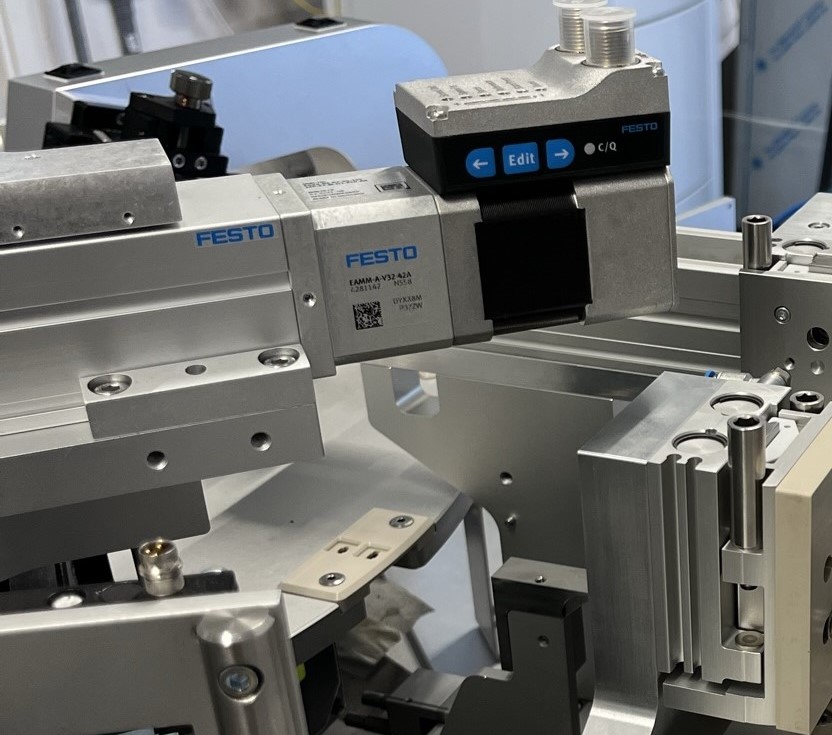

Fully automated change-out of components allow machines to switch between different formats.

For example, in packaging machinery, this may include adjustable guides, chutes, or feeders that are modified to handle various package sizes or configurations.

In manufacturing this could be part pickers, pneumatic spindles, grippers, bits, and tools.

The biggest benefit from a fully automatic machines is that they require only minimal human supervision and therefore can often have a bigger output than a semi automatic machines.

Our Fully Automatic machines for automation are tailored to meet each customers needs, and to efficiency, and productivity without any compromises.

Our Custom-made machines are designed to address unique needs by providing solutions that are tailored to individual customer requirements.

We have documented experience in developing and producing assembly machines for Medical devices and electronic components, both Fully Automatic and Semi-Automatic.

Fully Automatic Machines can optimize processes, reduce labor costs, minimize waste, and enhance overall efficiency, leading to improved profitability and competitive advantage.

Fully automated change-out of components allow machines to switch between different formats.

For example, in packaging machinery, this may include adjustable guides, chutes, or feeders that are modified to handle various package sizes or configurations.

In manufacturing this could be part pickers, pneumatic spindles, grippers, bits, and tools.

Our machines are be designed to perform the intended tasks accurately and reliably.

This involves understanding the desired operations and ensuring that the machine's design, components, and control systems are optimized for those tasks.

Depending on the application, precision and accuracy may be critical.

Our machines are capable of tasks with a precision of 0,01mm to ensure consistent and accurate results.

While the initial investment in custom machines can be higher compared to off-the-shelf solutions, they can provide significant cost savings in the long run. Custom machines can optimize processes, reduce labor costs, minimize waste, and enhance overall efficiency, leading to improved profitability and competitive advantage.

We don’t do standard solutions, and all our solutions are custom made to meet our customers requirements.

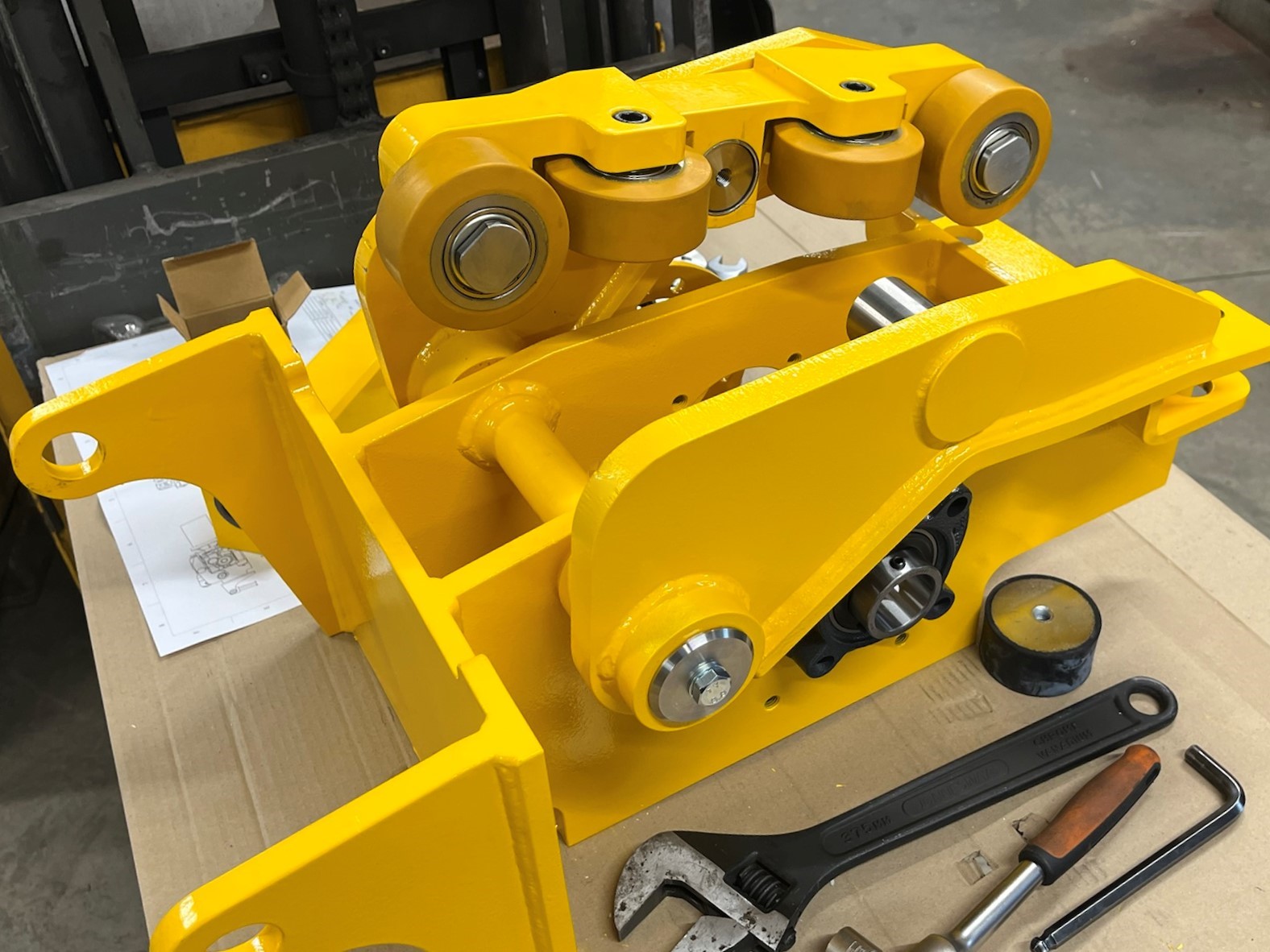

Our custom material handling equipment includes specialized lifting devices like lifting beams, or vacuum lifters, which can be designed to handle specific load types, sizes, and shapes.

Typically, the operator only have very limited workspace, so the solution must be invented smart, to make it possible to have assess to the workspace even though the space is very limited.

Our Custom machines are designed with safety features specific to the intended application.

They can incorporate safeguards, interlocks, and fail-safe mechanisms to protect workers from potential hazards. By automating risky or physically demanding tasks.

Our machines is made to create a safer work environment for our customers.

Standard Operating Procedures: Clearly documented standard operating procedures (SOPs) should be developed and followed for the safe operation of semi-automatic machines.

SOPs should cover machine setup, start-up, shutdown, routine maintenance, and emergency procedures.

Regular review and reinforcement of these procedures are important to maintain a safe working environment.